360 Degree Optical Sorting Machine

Category:

- DESCRIPTION

-

- Commodity name: 360 Degree Optical Sorting Machine

- Commodity ID: RK-1900 Series

Brand : RKE Product origin : CHINA Machine Feature:Using the artificial intelligence detection algorithm to automatically detect products appearance defects. Additional Installation Project:Can be customized automatic counting packaging machine and lifting machine according to client's needs. Delivery time : 30days

Friendly reminder!

This equipment is a customized device, and the model is developed and customized according to customer requirements. This platform only provides the demonstration of the equipment's function. If you need to order screening equipment, please contact us via email or phone.

Email:sales003@chinarke.com Contact number:+86 136 7016 1664

1. Product introduction

· Euipped with rotary index plate, stable and reliable, no stoppage, indexplate sorting machine can detect the objects need to be hangedwithout vibration, fast speed, and high accuracy.

· 360 degree inspect screw appearance defects and sizes, such as threaddamage, burrs, head cracks, verticality, etc.

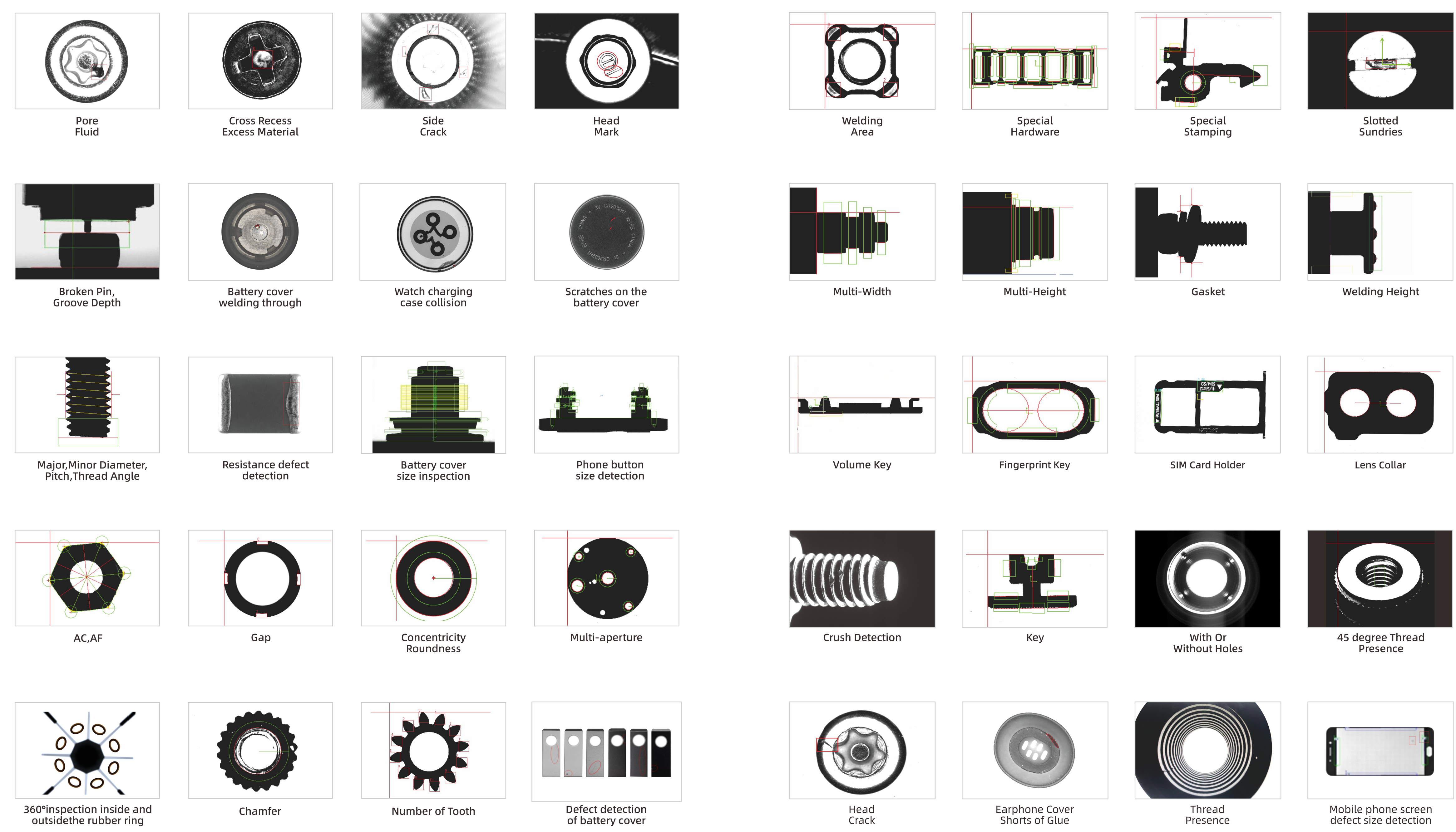

· Steel rotary index plates can be customized according to the diametersof the workpiece.2. Capable of Detection:

3. Inspection parameters:Including Dimensional characteristics, Head damage, Bit verification, Thread verification, Thread damage, Heat treat verification, Plating verification, Crack defects...

And more!

4. Product parameters for the optical sorting machine

Model: RK-1900 Head Diameter:

Ø1-Ø30mm

Height(mm):

5mm-40mm (Can be placed on the glass plate evenly.)

Sorting Accuracy:

±0.01mm (Based on the reference products supplied by customers as screening criteria for identification.)

Sorting Speed:

100-300pcs/min, According to individual case (objects and feeding system).

Air Pressure(kg/cm):

7kg/cm2

Mainframe computer Industrial pc Digital camera Industrial CCD Net weight(KGS) 650 Size 1500×1500×1800(LWH) Description for CCD Screening:

1)CCD1 Level Vision

2)CCD2 Upside 45°Vision

3)CCD3 Downside 45°Vision

4)CCD4 Lateral Vision

5)CCD5 Upward Detection

6)CCD6 Downward Vision

5.Optical Sorting Machine Factory Price Features:

1. Installing a 360° camera can meet the customer's higher detection requirements and accurately detect the size of the product more comprehensively

2. Designed For general fastener size, and can detect the products screw nuts, aviation fasteners, auto parts, mobile phone accessories, rubber pieces, electronic products, hardware products.

3. Can be added 9-13Cameras based on your cases.

4. Can increase the automatic packing machine and automatic feeding machine according to customer’s demand.

5. Replacement parts fast, simple operation.

6. User-friendly software.

CONSULTATION

Ready to work with us ?

Sales hotline:

Rosaline +86 13670161664

After sales hotline:

+86-769-86712036 / 82970058 / 82970118

Email: sales003@chinarke.com

Address:

7th Floor, Building A2, Songhu Zhigu, Liaobu Town, Dongguan City, Guangdong Province

Follow us

Copyright 2023 Dongguan RKE Intelligent Technology Co., Ltd.